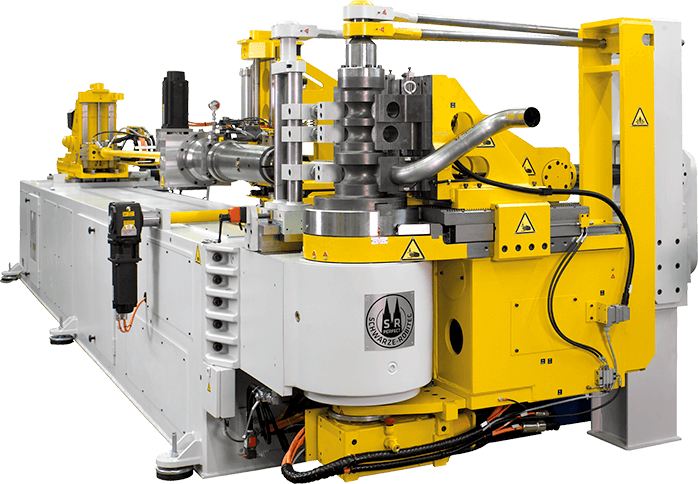

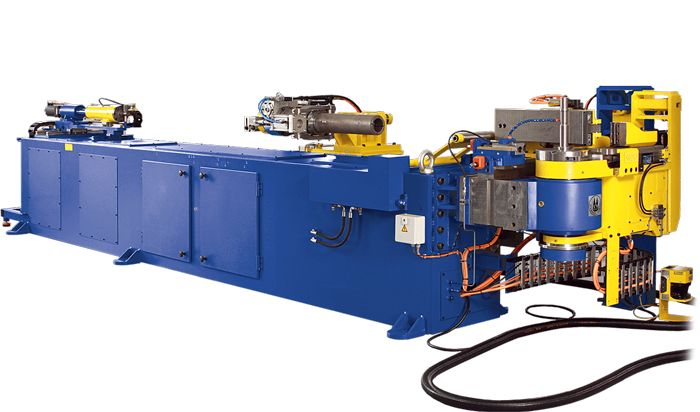

Our flexible CNC MR tube bending machines equip you for every task

The ideal solutions for the production of different bending radii, bend-in-bend systems and tube systems such as manifolds and exhaust pipes for the automotive industry are the CNC MR mandrel bending machines equipped with multi-stack bending tools and multiple clamp jaws.

Their multi-level technology combined with customisable tools ensures the easy and precise bending of tubes with very short intermediate lengths between the individual bends. This makes it possible to produce, for example, exhaust pipes with a bending radius of 1 x D without any straight intermediate lengths between two bends. In those applications where a high level of flexibility is required within a process step, it is preferable to use a multi-stack machine rather than the single-stack variant because it compensates any possible additional costs through less frequent refitting.

Benefits in series and large-scale production

As a part of our HIGH PERFORMANCE range, our multi-stack CNC tube bending machines are designed to meet the requirements of series and large-scale production. They enable you to satisfy even the most challenging tube bending requirements at high speed without any need to compromise on manufacturing quality. Our high quality standards mean you can reduce downtimes and unnecessary interruptions of your production processes to a minimum.

CNC 18

max. Ø 18mm

CNC 80

max. Ø 80mm

CNC 220

max. Ø 203,2mm

CNC 25

max. Ø 25mm

CNC 100

max. Ø 114,3mm

CNC 40

max. Ø 40mm

CNC 130

max. Ø 130mm

CNC 60

max. Ø 60mm

CNC 160

max. Ø 160mm

A reliable partner by your side

Technologies like our multi-stack bending tools and multi-level solution set the standard for innovation and high quality “Made in Germany”. Decades of experience in collaborating with many companies in various industries have given us the necessary expertise to develop customised solutions for your needs. The combination of our first-class tube bending technologies, an extensive range of smart add-on modules and a global service offering provide you with a unique, high-performance and future-proof package.

The benefits at a glance

Our multi-stack CNC tube bending machines are often the smart solution for more complex tube bending tasks in series and large-scale production. If you would like any further information or you need advice about your individual specifications, please contact us without obligation.

-

Suitable for many uses

-

Fast, efficient and precise

-

Multi-radius technology

-

Extensive range of optional extras

-

Short setup times

-

For complex geometries bent in one direction on multiple planes

-

Suitable for three-shift operation

-

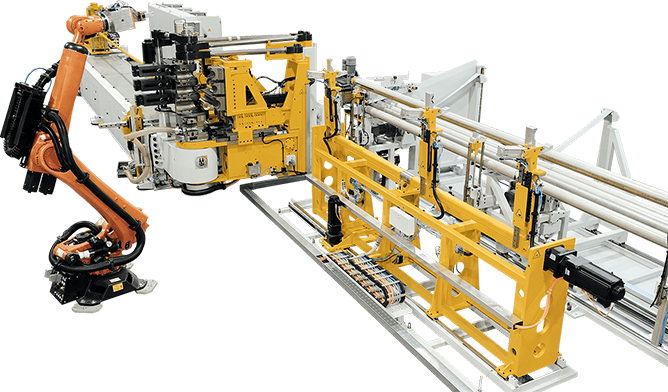

Automation option available

Customised bending solutions: more than the sum of their parts

Individual requirements call for individual solutions – the entire package needs to be right.

Our modular machine and accessory ranges enable us to work with you to tailor the most efficient tube bending solution for your application. From optimal tooling for your machine and smart and user-friendly control systems to high-precision measuring devices and software-based tube bending simulation: there are virtually no limits to the available options. Our many years of experience working with customers in different industries helps us to find the right technology and service solutions for your specific requirements.

HIGH PERFORMANCE – tube bending machines for series and large-scale production

The CNC tube bending machines from our HIGH PERFORMANCE range are the perfect answer to the exacting requirements of series and large-scale production. Thanks to their speed, performance and flexibility, our modular tube bending solutions allow fast cycle times without compromising manufacturing quality.

We offer different approaches to suit every requirement. In addition to our multi-stack machines, we supply a wide range of single-stack machines, machines with two bending heads for especially complex tube geometries and complete bending cells as fully automated package solutions.

Please feel free to contact us for advice about the right machine for your needs.

The world’s leading expert in tube bending machines

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.