Effizient, zuverlässig und flexibel:

unsere HIGH PERFORMANCE Rohrbiegemaschinen

Die Maschinen aus unserer HIGH PERFORMANCE Serie sind speziell für die anspruchsvollen Rohrbiegeanforderungen der Serien- und Großserienproduktion entwickelt worden. Mit hoher Wiederholgenauigkeit und Präzision biegen sie Rohre aus allen gängigen Materialien wie Aluminium, Titan, Kupfer, Stahl und Edelstahl mit einem maximalen Rohrdurchmesser von 160 mm. Ausgestattet mit einer intuitiv bedienbaren CNC-Steuerung ermöglichen die Kaltbiegemaschinen ihren Anwendern eine zeit- und kosteneffiziente Fertigung von einfachen oder komplexen Rohrgeometrien. Darüber hinaus können die Maschinen durch ein umfangreiches Zubehörprogramm Ihren individuellen Anforderungen entsprechend an Ihren Produktionsprozess angepasst werden.

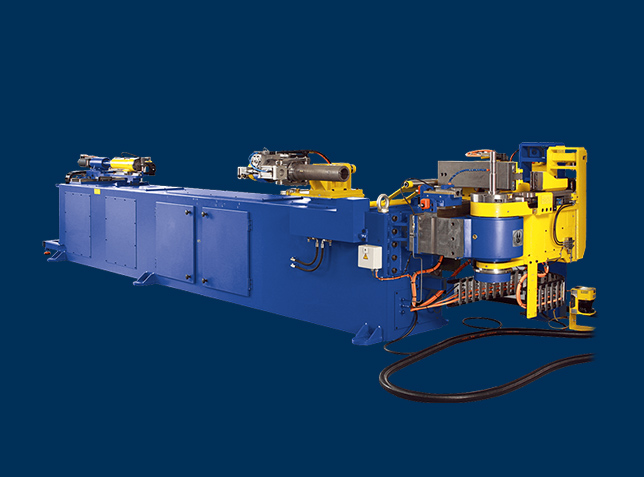

Einrillige Rohrbiegemaschinen

Schnell, leistungsstark und flexibel: Unsere einrilligen CNC-gesteuerten Rohrbiegemaschinen sind echte Allround-Talente. Dank kurzer Rüstzeiten, höchster Geschwindigkeit und maximaler Genauigkeit eignen sie sich hervorragend für Fertigungsprozesse in Branchen, die hohe Anforderungen an das Produktionsvolumen setzen.

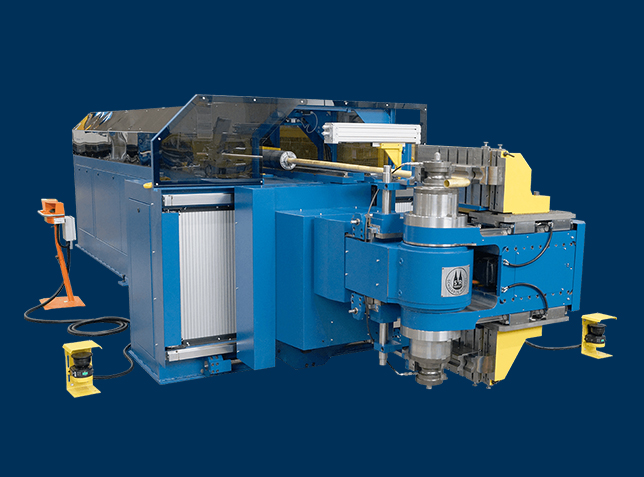

Mehrrillige Rohrbiegemaschinen

Mit unseren mehrrilligen Dornbiegemaschinen gestalten Sie Ihren Produktionsprozess dank optimierter Umrüstzeiten noch zeiteffizienter. Unsere CNC MR-Serie ist die Lösung, wenn es um flexible Biegeprozesse geht. Dank Multiradiustechnik gelingt auch das Umformen von Rohren mit sehr kurzen Zwischenlängen zwischen den einzelnen Biegungen in kürzester Zeit.

Rohrbiegemaschinen mit zwei Biegeköpfen

Die Rohrbiegemaschinen CNC Rotary und CNC Twin ermöglichen eine zeitsparende und wirtschaftliche Herstellung von mehrdimensionalen Rohrsystemen. Links- und Rechtsbiegen in einem Arbeitsgang – dank moderner CNC-Technologie lassen sich so selbst komplexeste Geometrien ohne Schweißnaht in einem einzigen Arbeitsschritt entstehen.

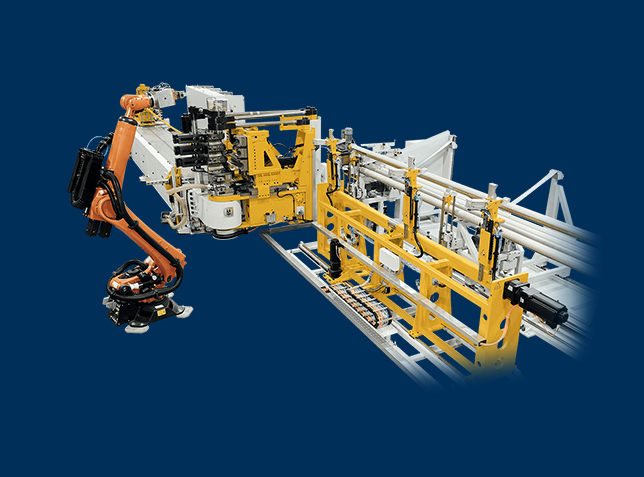

Vollautomatische Biegezellen

Eine vollautomatisierte Biegezelle verschafft Ihnen den Vorteil einer optimal abgestimmten und somit besonders konstanten und planbaren Komplettlösung rund um Ihre Rohrbiegemaschine. Durch ein großes Spektrum an zusätzlichen Funktionen kann jede CNC-gesteuerte Rohrbiegemaschine unserer HIGH PERFORMANCE-Serien zu einer vollautomatischen Lösung ausgebaut werden.

Maßgeschneiderte Biegelösungen: Mehr als die Summe ihrer Teile

Individuelle Anforderungen brauchen individuelle Antworten – das Gesamtpaket muss stimmen!

Unser modular konfigurierbares Maschinen- und Zubehörprogramm ermöglicht es uns, mit Ihnen gemeinsam die effizienteste Rohrbiegelösung auf Ihren Einsatzzweck hin maßzuschneidern. Von der optimalen Werkzeugbestückung Ihrer Anlage über eine smarte und anwenderfreundliche Steuerung bis hin zur hochpräzisen Messanlagen und softwarebasierter Rohrbiegesimulation: den Möglichkeiten sind fast keine Grenzen gesetzt! Unsere langjährige Erfahrung mit Kunden unterschiedlichster Branchen hilft uns dabei, passende Technologie- und Service-Lösungen für Ihre spezifischen Anforderungen zu finden.

Weltweit führender Experte für Rohrbiegemaschinen

Seit Jahrzehnten sind wir ein weltweit führendes Unternehmen in der Entwicklung und Fertigung hochwertigster Rohrbiegemaschinen. Von Maschinen für die Einzelfertigung und kleine Losgrößen über Rohrbiegemaschinen für die Großserie bis hin zu Spezialisten für besondere komplexe Rohrgeometrien – für jeden Rohrdurchmesser und Anwendungszweck, für jede Industrie bieten wir die passende Lösung. Ob als hydraulische, (teil-)elektrische oder hybride Ausführung, ob als smartes ECO-Line-Paket oder in Kombination mit unserem modularen Ausstattungsoptionen – in unserem Portfolio finden Sie die richtige Antwort auf Ihre spezifischen Anforderungen.

Nehmen Sie mit uns Kontakt auf, gerne beraten wir Sie zu passenden Antworten auf Ihre Anforderungen!