Efficient, reliable and flexible: our HIGH PERFORMANCE tube bending machines

The machines from our HIGH PERFORMANCE range have been developed specifically to meet tube bending challenges in series and large-scale production. Working with a high degree of reproducibility and precision, they can bend tubes with a maximum diameter of 160 millimetres made from all standard materials such as aluminium, titanium, steel and stainless steel. The cold bending machines equipped with an intuitive CNC control enable users to manufacture both simple and complex tube geometries quickly and cost-efficiently. Moreover, an extensive accessory set means the machines can be customised to the individual requirements of your production process.

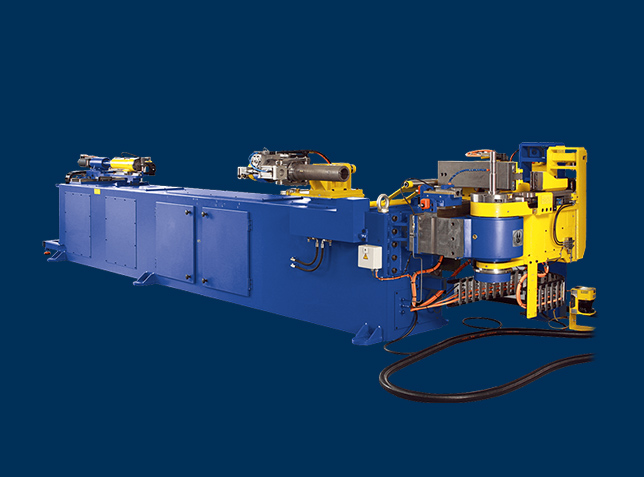

Single-stack tube bending machines

Fast, powerful and flexible: our single-stack CNC tube bending machines are true all-rounders. Thanks to short setuo times, high speeds and maximum precision, they are ideal for use in manufacturing processes in industries that place high demands on production volume.

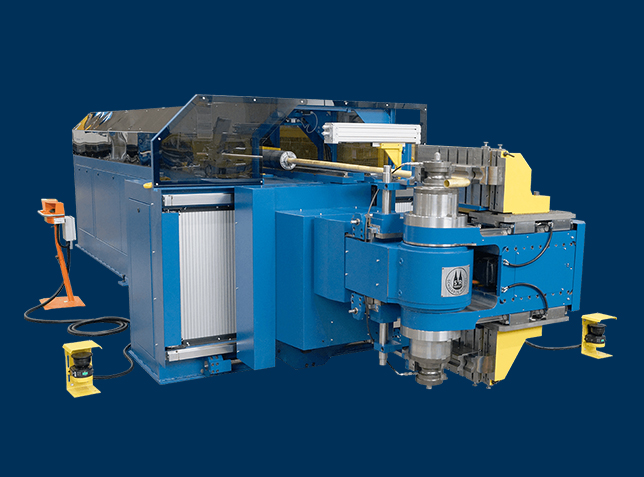

Multi-stack tube bending machines

Thanks to their optimised setup times, our multi-stack mandrel bending machines enable you to make your production process even more efficient. Our CNC MR range is the solution for flexible bending processes. Multi-radius technology makes it possible to bend tubes with very short intermediate lengths between the individual bends in a very short time.

Tube bending machines with two bending heads

The CNC Rotary and Twin tube bending machines allow the time-saving and economical production of multi-dimensional tube systems. Thanks to state-of-the-art CNC technology, left-and-right bending and even the most complex geometries without a single weld can be produced in just one operation.

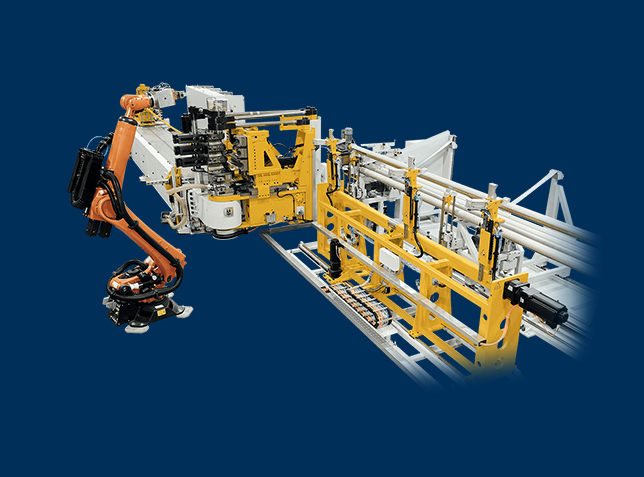

Fully automated bending cells

A fully automated bending cell gives you the advantage of a perfectly harmonised, consistent and reliable all-in-one solution built around your tube bending machine. A wide range of additional functions means that any CNC tube bending machine from our HIGH PERFORMANCE range can be expanded to create fully automated solutions.

Customised bending solutions: more than the sum of their parts

Individual requirements call for individual solutions – the entire package needs to be right.

Our modular machine and accessory ranges enable us to work with you to tailor the most efficient tube bending solution for your application. From optimal tooling for your machine and smart and user-friendly control systems to high-precision measuring devices and software-based tube bending simulation: there are virtually no limits to the available options. Our many years of experience working with customers in different industries helps us to find the right technology and service solutions for your specific requirements.

The world’s leading expert in tube bending machines

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.